Add to Enquiry Bag

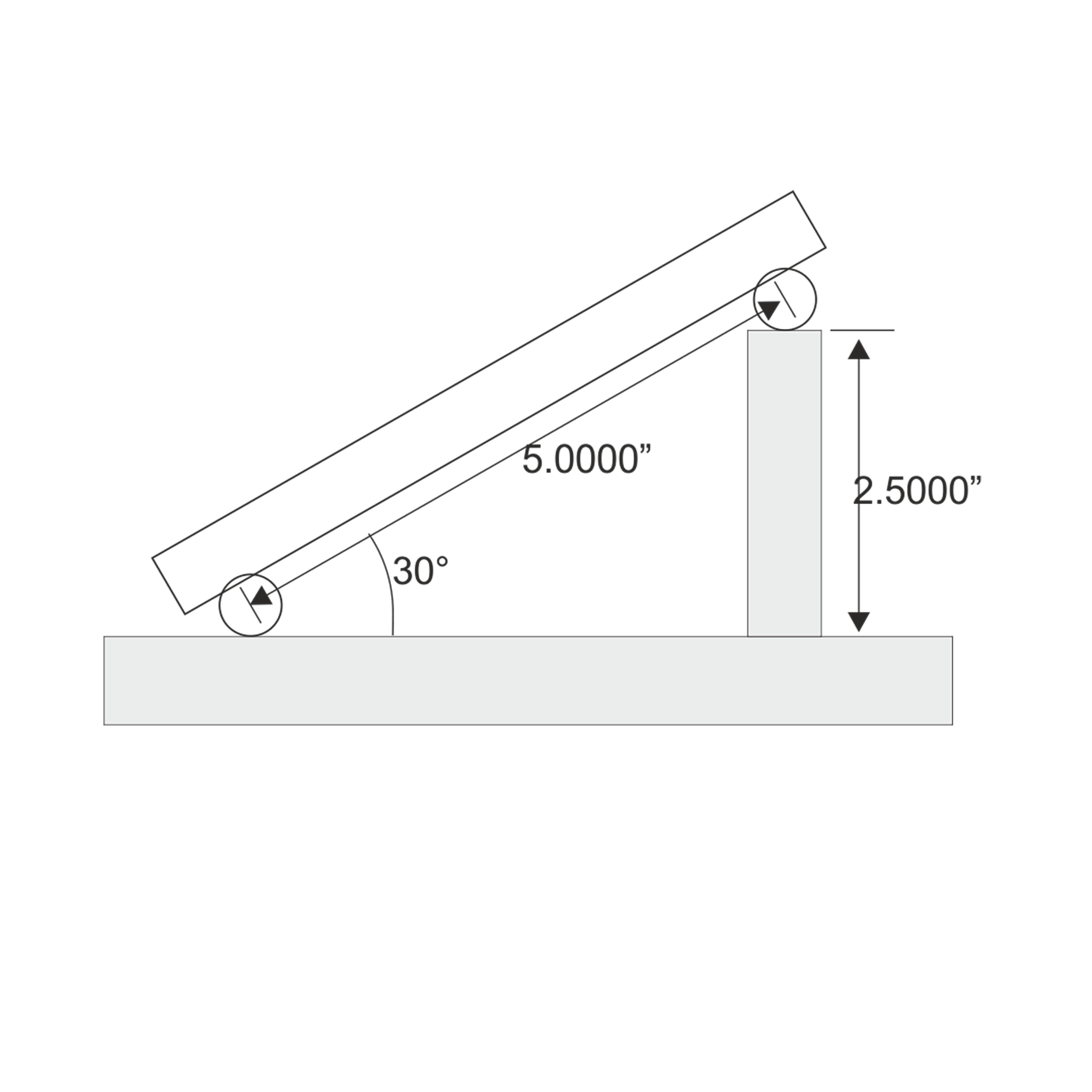

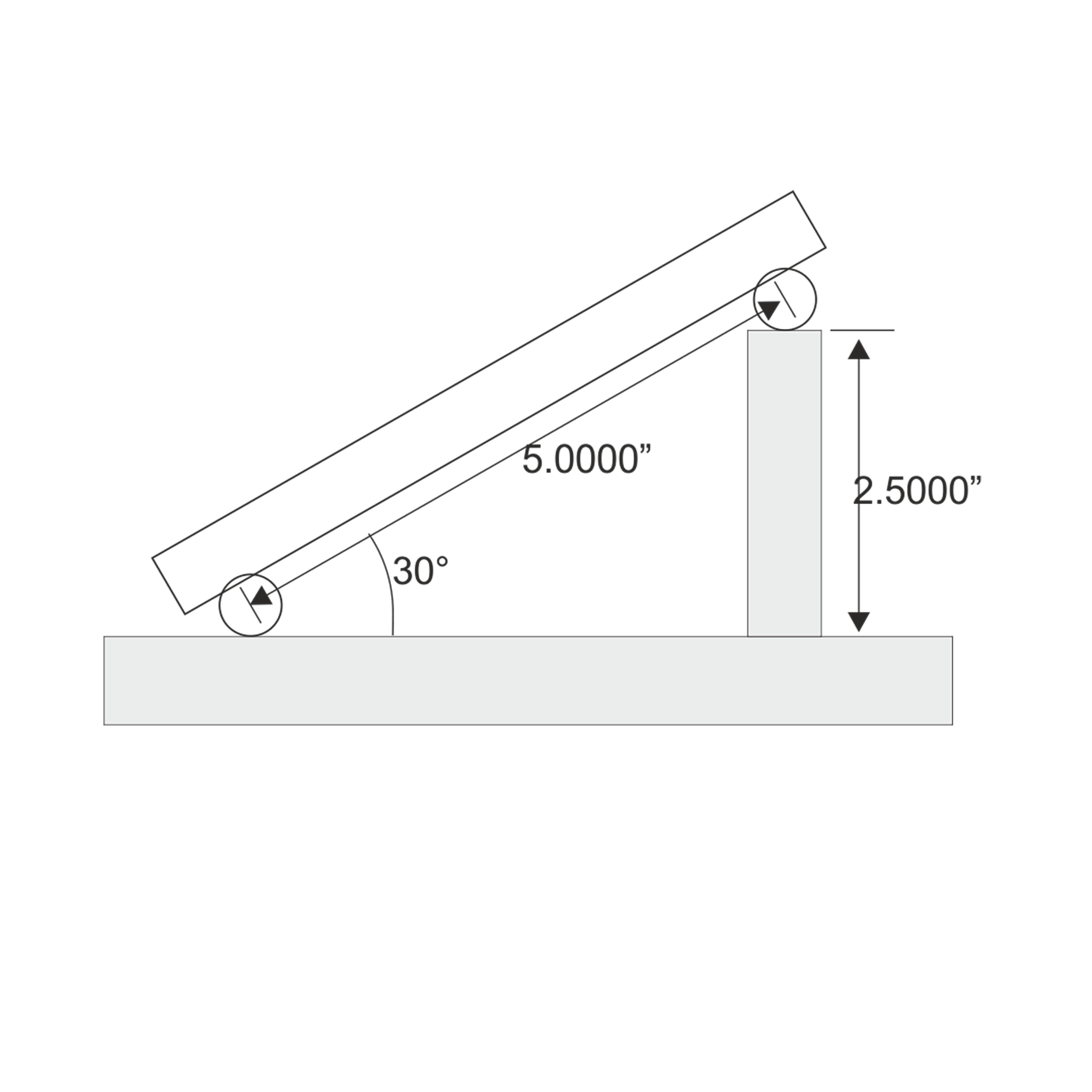

Enquire NowPerfect for angular inspection and measurement . Made of hardened steel. Ground square and parallel within .0002” The Sine-Bar is used to setup angles on a Layout Table or in a Milling Machine Vice. This is done by using a bar with two pins mounted at an accurate predetermined distance. One end is raised to a measured height by using gauge blocks or an adjustable parallel. Perfect for angular inspection and measurement . Made of quality tool steel, hardened and ground for extreme accuracy . Ground square and parallel within .0002" (0.005mm) The sine bar is the hypotenuse of a right angled triangle. The 2.5" gage block is the opposite side of the triangle. As you can recall the trigonometry we learned back in high school, sin theta = the opposite over the hypotenuse, or sin theta = 2.5/5 = .5.

( SOH CAH TOA, sin theta=opp/hyp, cos theta=adjacent/hyp, tan theta = opp/adj.).

Likewise we can figure the height of the needed gage block for a particular angle by finding the sin of the angle and multiplying by the hypotenuse. sin(30)*5 = .5*5 = 2.5". If you look at the drawing you will observe that the rolls raise the triangle by the roll radius, this does not matter as the triangle is still parallel to the surface plate.

| Ordering No. | Width | Height | Distance Between Roller | Net Weight Kgs. |

|||

|---|---|---|---|---|---|---|---|

| Inch | mm | Inch | mm | Inch | mm | ||

| 111700 | 1 | 29.4 | 1.1/4 | 32 | 4 | 100 | 0.70 |

| 111710 | 1 | 25.4 | 1 | 25.4 | 2.1/2 | 63 | 0.30 |

| 111720 | 1 | 25.4 | 1 | 25.4 | 5 | 125 | 0.40 |

| 111730 | 1.3/16 | 30 | 1.1/4 | 32 | 6 | 150 | 0.80 |

| 111740 | 2.3/8 | 60 | 1.7/8 | 48 | 8 | 200 | 3.80 |

Boring Head Kits

Precision Milling Machine Vises

Precision Tilting and Swiveling Machine Vises

Checkout our latest

Product Catalogues